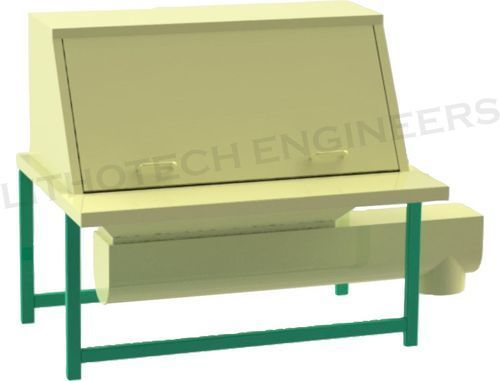

Dump Booth

Product Details:

- Features Open front access, easy cleaning, in-built filtration system, LED indication, low maintenance

- Power Source Electric

- Surface Finish Powder coated and SS polish

- Thickness 2 mm to 3 mm

- Material Mild steel (MS) structure, Stainless steel (SS) contact parts

- Type Dump Booth

- Structure Sturdy MS frame with SS panels

- Click to View more

X

Dump Booth Product Specifications

- Open front access, easy cleaning, in-built filtration system, LED indication, low maintenance

- Not Included

- Dump Booth

- Corrosion resistant, Chemical resistant

- 220-240V

- Powder coated and SS polish

- Electric

- 2 HP to 5 HP

- Sturdy MS frame with SS panels

- Variable (customizable as required)

- For dust-controlled dispensing and material dumping in pharma, chemical, and food industries

- Not Included

- 2 mm to 3 mm

- Mild steel (MS) structure, Stainless steel (SS) contact parts

- 500 kg to 2000 kg

- Export quality wooden crate packaging

- Integrated LED light

- External vacuum port & removable pre-filter

- Floor mounted

- Emergency stop button, overload protection

- 1000 to 3000 m³/hr

- < 70 dB

- Sliding acrylic or polycarbonate

- HEPA filter (High Efficiency Particulate Air)

- Custom as per user requirement

- Microprocessor-based controller

Dump Booth Trade Information

- All India

Product Description

During transfer or dumping operations, a Dump Booth is a type of equipment used to safely contain and handle hazardous or volatile materials. Usually, a strong frame and panels made of resilient materials like polycarbonate or acrylic make up the booth. It is frequently used in sectors like manufacturing, chemicals, and pharmaceuticals where handling materials could be hazardous to health or safety. The Dump Booth's purpose is to contain any dust or fumes that may be released during the transfer or dumping process and keep them from leaking outside the enclosure and harming the environment.

Advanced Filtration and Cleanliness

Equipped with a HEPA filter and a removable pre-filter, this Dump Booth captures airborne particulates during material dumping. The external vacuum port simplifies routine cleaning, minimizing dust exposure for operators and maintaining a contamination-free workspace.

Intuitive Safety and Control Features

Safety is prioritized with an emergency stop button, overload protection, and a microprocessor-based control system. These features guarantee reliable operation and quick intervention in case of unexpected events, fostering a secure working environment for users.

Customizable for Diverse Industry Needs

The Dump Booth is tailored for pharmaceuticals, chemical, and food industries. Its customizable size, variable speed control (2 HP5 HP), and corrosion-resistant construction make it a versatile solution for various dispensing applications, with export-grade packaging ensuring safe delivery.

FAQs of Dump Booth:

Q: How does the HEPA filter in the Dump Booth benefit dust control during material transfer?

A: The HEPA filter efficiently captures fine particulates generated during material dumping, maintaining a clean environment and protecting both operators and products from airborne contaminants.Q: What cleaning process should be followed for the Dump Booth?

A: Cleaning is facilitated by the external vacuum port and the removable pre-filter. Regular vacuuming and periodic replacement or cleaning of the pre-filter ensure optimal filtration performance and minimal maintenance effort.Q: When is it necessary to use the Dump Booth in industrial applications?

A: The Dump Booth should be used whenever dust-controlled dispensing is required, particularly in pharmaceutical, chemical, or food processing environments where contamination control is critical.Q: Where can the Dump Booth be installed within a facility?

A: This floor-mounted booth can be placed in designated dispensing or material handling areas. Its dimensions are customizable to fit available space and workflow requirements.Q: What safety features are included in the Dump Booth to protect operators?

A: Operator safety is ensured through an emergency stop button, overload protection, sliding doors made of impact-resistant materials, and an advanced control system that manages booth operations securely.Q: How does the microprocessor-based controller enhance booth operation?

A: The microprocessor controller enables precise management of airflow, speed, lighting, and safety functions, allowing users to maintain optimal conditions for material handling and maximizing booth efficiency.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese